LEYLAND MOTORS LIMITED

History

In 1896 the Lancashire Steam Motor Co. was formed. In 1907 it joined the Coulthard & Co. engineering firm of Preston & was renamed Leyland Motors. By 1950 Leyland was Britain’s biggest manufacturer of bus, coach, truck chassis & commercial vehicle engines.

Specification

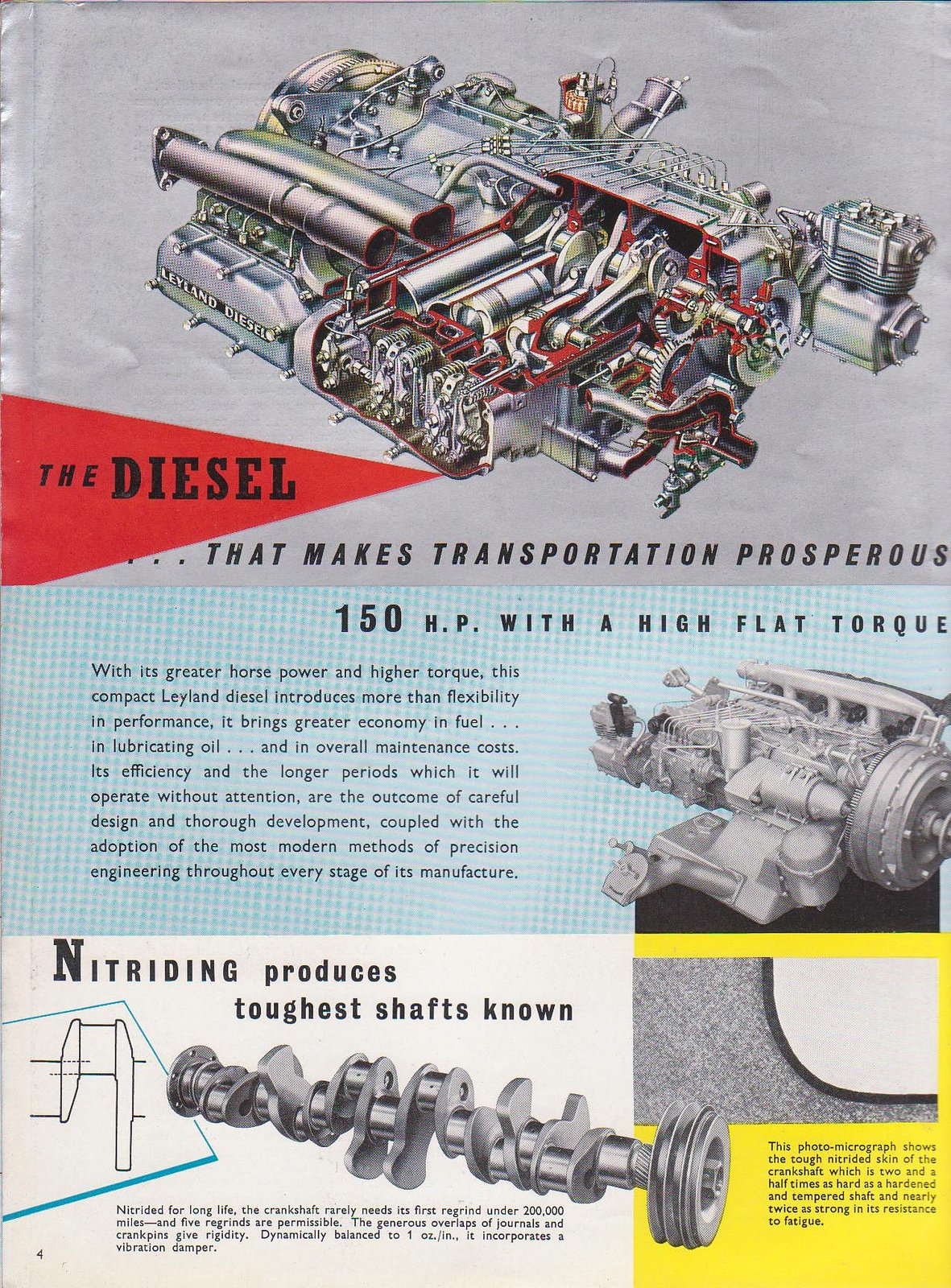

The O.600 engine is identified by its cubic inch displacement, which equates to 9.8-litres. The ‘O’ stands for oil engine - a British term for compression-ignition (i.e. ‘diesel’) engine.

The O.600 had a 4 4/5inch bore & 5½ stroke. In buses, the engine is rated at 125bhp at 1,800rpm, with peak torque of 410lbft at 900rpm. In coaches it's uprated to 130bhp at 2,200rpm The Leyland O.600 engine is under-stressed & capable of giving lively, yet economic performance. It has the ability to run hundreds of thousands of miles between overhauls. A major structural feature of the O.600 was the dry-liner cylinder block & single cast crankcase. The first UK heavy vehicle engine to feature this.

The O.600 is a 6-cylinder, direct-injection, pushrod overhead valve unit. The cylinder head is split into two, with each head & gasket unit covering three-cylinders. Design features which enhance reliability are: a gear-driven camshaft, mounted low in the block; a nitride crankshaft running in strip-bearings & chromium-plated piston-rings.

Over the years the engine had many modifications. In 1960 a Power-Plus version was launched, with spheroidal combustion chamber cavities, giving more power & fuel efficiency.

New Paragraph

From 1946 the Leyland 600 engine was first used in Leyland truck chassis (Beaver, Hippo, Octopus & Steer). From 1947 it was used in Leyland PS2 Tiger (saloon) & PD2 Titan (double deck) buses.

Horizontal Use

In 1947 the horizontal 600 was developed. Laid on its side the engine is 1-foot 10-inches high. The main difference from the vertical model was a redesigned sump, longer engine oil filler spout & dipstick. Auxiliary units, (alternator & fuel pump), air intake/exhaust manifolds were relocated & redesigned to improve access from the side.

The first horizontal 600 engines went to Swedish bus maker Scania in 1947. Leyland introduced the horizontal 600 at the 1948 Commercial Motor Show (Earls Court), where the new Leyland/MCW Olympic bus was powered by it.

Leyland used this engine in Tiger, Royal Tiger, Worldmaster & Titan. Also some early Leopard’s, Atlantean’s & some Panther’s.

From 1951 to 1953 RED & WHITE bought 68 Leyland Royal Tiger saloons powered by the Leyland 600 engine. They were obviously impressed with their performance on hilly routes in South Wales. So, when they were replaced in 1967 the company bought 21 Bristol RESL’s with the same engine. The only survivor is LAX 101E.

RED & WHITE & Leyland O.600 engines

Other Bristol RE's with Leyland 600 engines, RED & WHITE bought:

- five RELL buses in 1967,

- ten Bristol RELH coaches in 1968 (includes Ruby),

- twenty RELL buses in 1968,

- eleven

RELH’s coaches in 1969.

New Paragraph

"The greatest pleasure of a Leyland-engine BRISTOL RE is the noise!"

Only a few companies bought Bristol

RE’s powered by the Leyland 600 engine, those that did include:

- Cumberland Motors (had 37)

- Luton Corporation (had 30)

- Newport Corporation (had 8)

- RED & WHITE (had 67). Details.

All other operators (e.g. Bristol Omnibus) that bought Bristol

RE's

powered by a Leyland engine, choose the slightly more powerful Leyland 680 unit.

Ruby's Leyland O.600 engine

A short video (taken through the floor trap inside the coach), of Ruby's Leyland O.600 diesel engine on tick-over.

Turn-up the sound & enjoy!

You're looking at the engine air in-take manifold (top of screen), the very small fuel delivery pipes & top of the coolant water jacket.

Postscript

By the mid 1970’s RED & WHITE recognised that the 600 engine was a bit under-powered for coach work & introduced a programme to retro-fit all its Bristol RELH’s with Leyland 680 engines. Ruby never gained the larger 680 engine. So, she's now the only surviving Bristol RELH powered by a Leyland 600 engine.

Component Suppliers

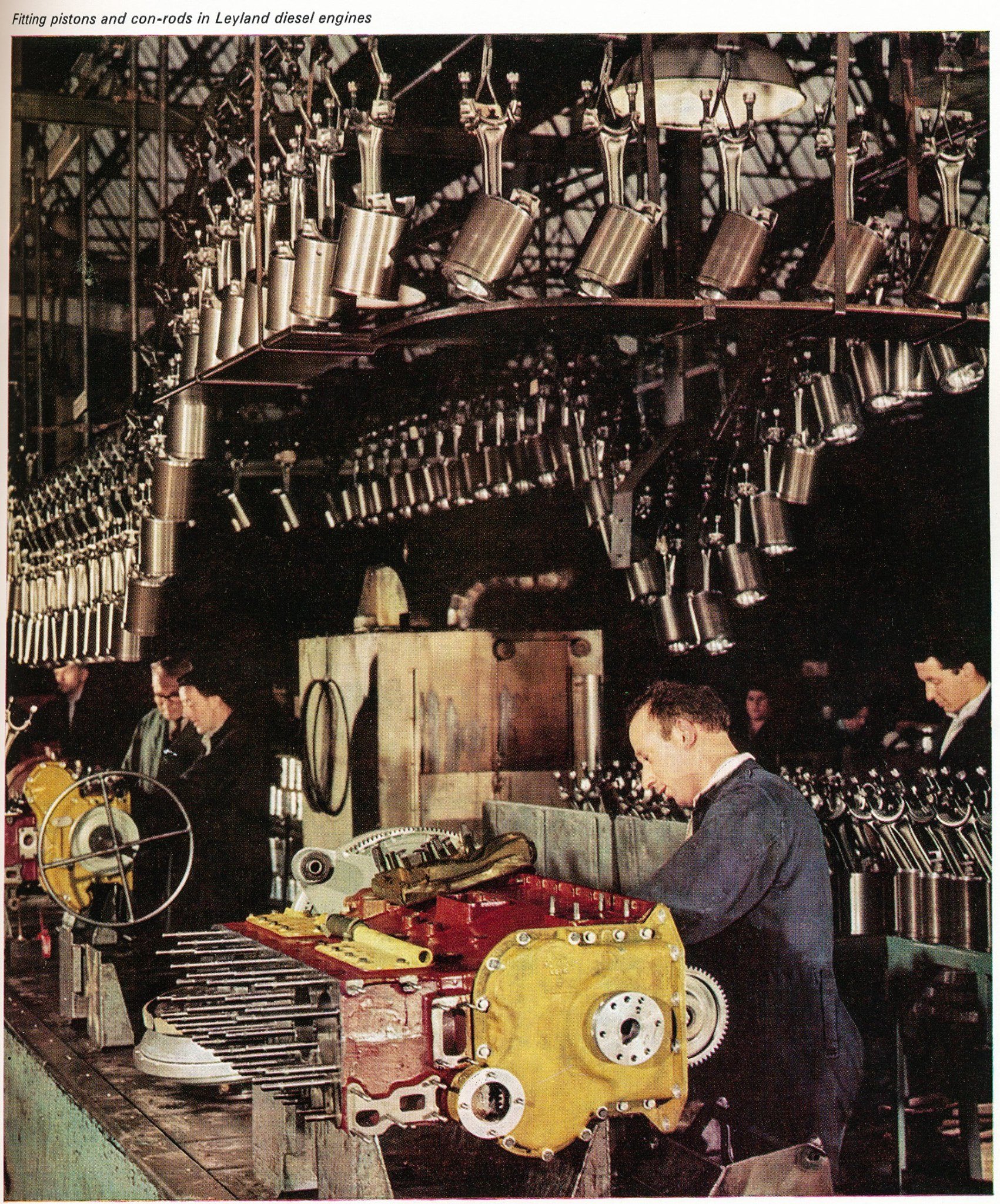

Leyland Motors Ltd made most of the engine themselves, in their own foundry & assembly line in Leyland, Lancashire. However, they bought-in certain specialist parts. CAV supplied Leyland with diesel injectors, fuel lift & injection pumps, 24-volt starter motors & 24-volt alternators. Ruby has these components fitted to her engine.

Gearbox

From 1951 Leyland Motors Ltd had a shareholding in Coventry-based

Self-Changing Gears, a manufacturer of vehicle gearboxes.

Ruby's

gearbox uses gears made by SCG.

Technical data has been drawn from the ‘Leyland Bus Mk 2’ book by D. Jack (May 1984).

View details of the rebuild of Ruby's engine, spring 2017.