History

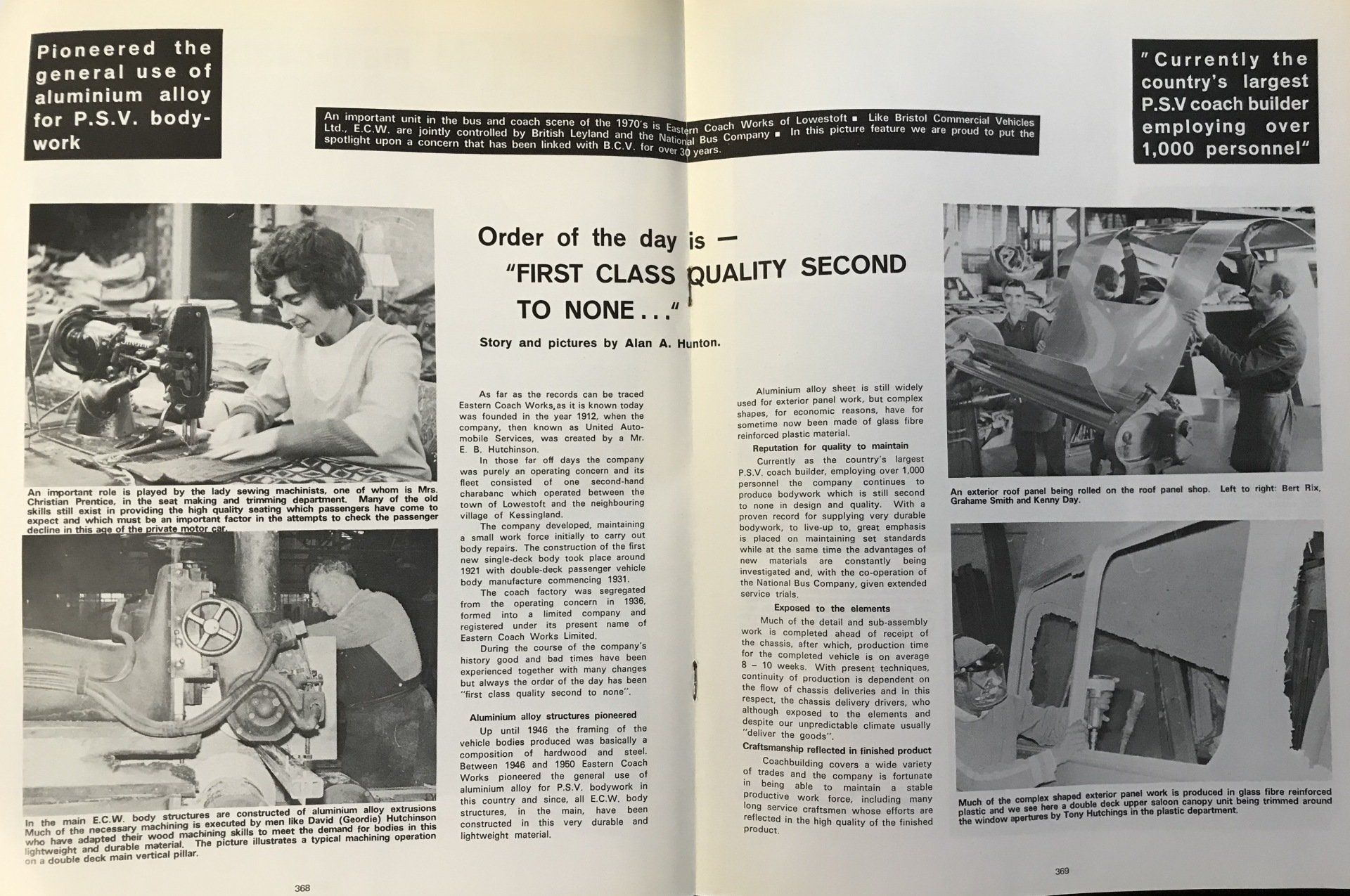

In 1912 United Automobile started running local bus services in Lowestoft. They began constructing bus & coach bodywork in the town in 1920. In 1931 the East Anglia operations of United were sold to a new Eastern Counties Omnibus Company, who inherited the coachworks & over 600 staff.

In July 1936, the coachworks were separated from the bus company & became Eastern Coach Works. ECW was by now part of the Tilling Group of bus companies.

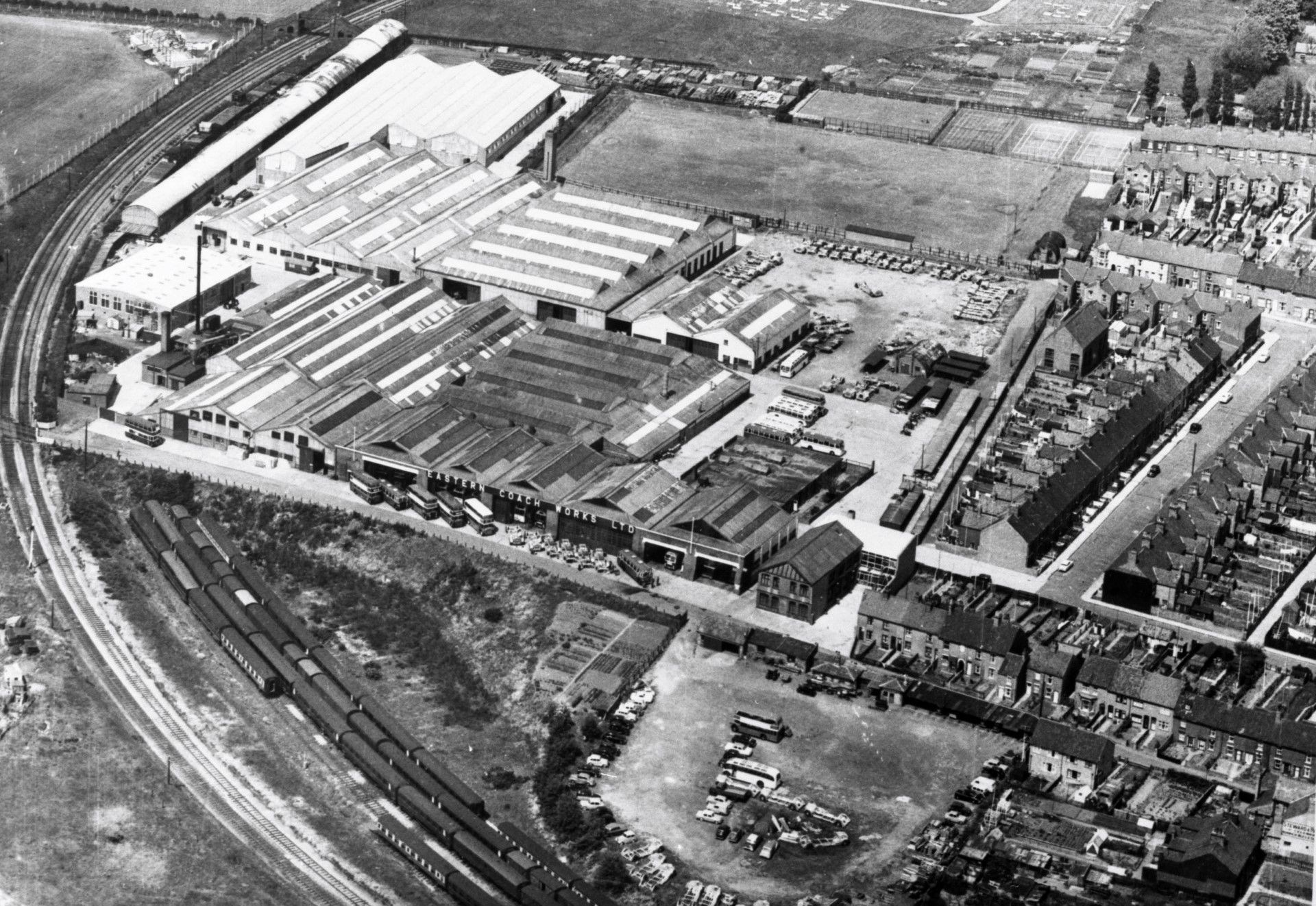

At its peak ECW had 1,200 employees on its 30-acre site, off Laundry Way (later renamed Eastern Way), Lowestoft.

In May 1940, the Government ordered ECW to stop production, in case of a possible German invasion. All vehicles were moved from the site to stop them falling into enemy hands. 950 staff were laid off.

Nationalisation

The Labour Government of 1945 planned to nationalise all road & rail transport. ECW was nationalised in 1947, the year production returned to pre-War levels. For the next 18 years, it built coachwork, mainly on Bristol chassis, for state-owned operators (in the Tilling Group of bus companies).

In 1965, the state-owned Transport Holding Company sold a 25% share in ECW to Leyland Motors. This allowed ECW to sell to municipal & independent bus companies again.

In 1969, ECW became part of a 50/50 joint venture between the new National Bus Company (founded 1 January 1969) & British Leyland.

The joint venture ended in 1982, when British Leyland took control of ECW.

The privatisation of Britain's state-owned bus companies & de-regulation of bus services in 1986 resulted in a dramatic fall in orders for new full-size buses. The last 260 bodies built by ECW were on Olympian chassis for London Buses. Leyland closed the ECW factory in January 1987.

The buildings were then demolished. The factory site is now North Quay Retail Park.

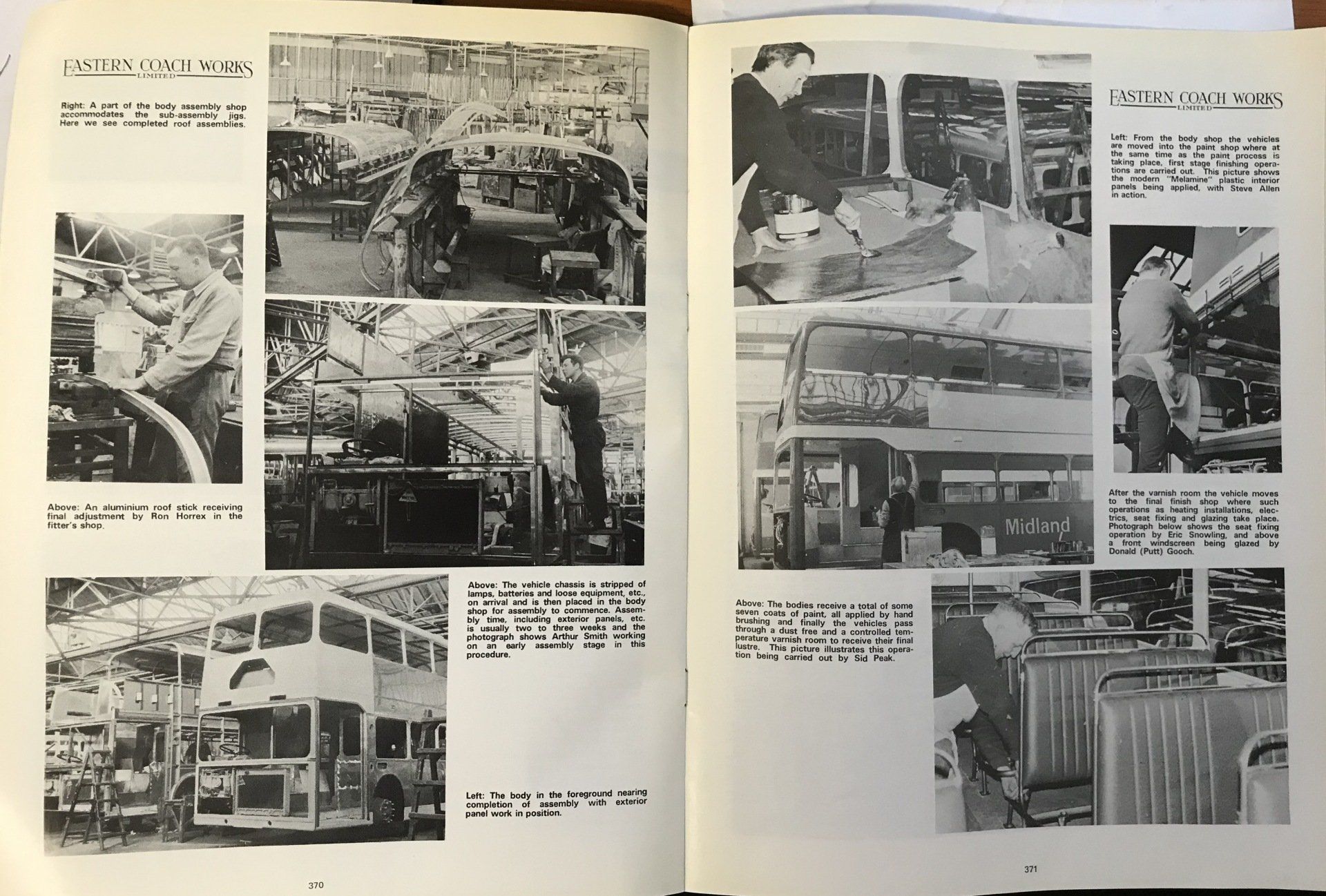

Manufacture

From 1946 ECW bodies were built using aluminium frames & aluminium panelling. Aluminium is light, strong & does not rust. ECW frames were known for their long & trouble-free service-life. However, the use of hardwood in some parts of their coachwork did suffer rot after many years in service.

ECW also made extensive use of moulded fibre-glass for front and rear panels; roof domes; side locker doors; interior luggage racks & the interior dashboard.

ECW coachwork was hand painted & varnished.

The skilled ECW craftsmen manufactured most of the coachwork themselves by hand from raw materials - aluminium, steel, hardwood & fibreglass. Specialist parts were bought-in from British manufacturers.

Component Suppliers to ECW

- Brifex - leather cloth, for interior side panels; front & rear domes; underside of luggage racks.

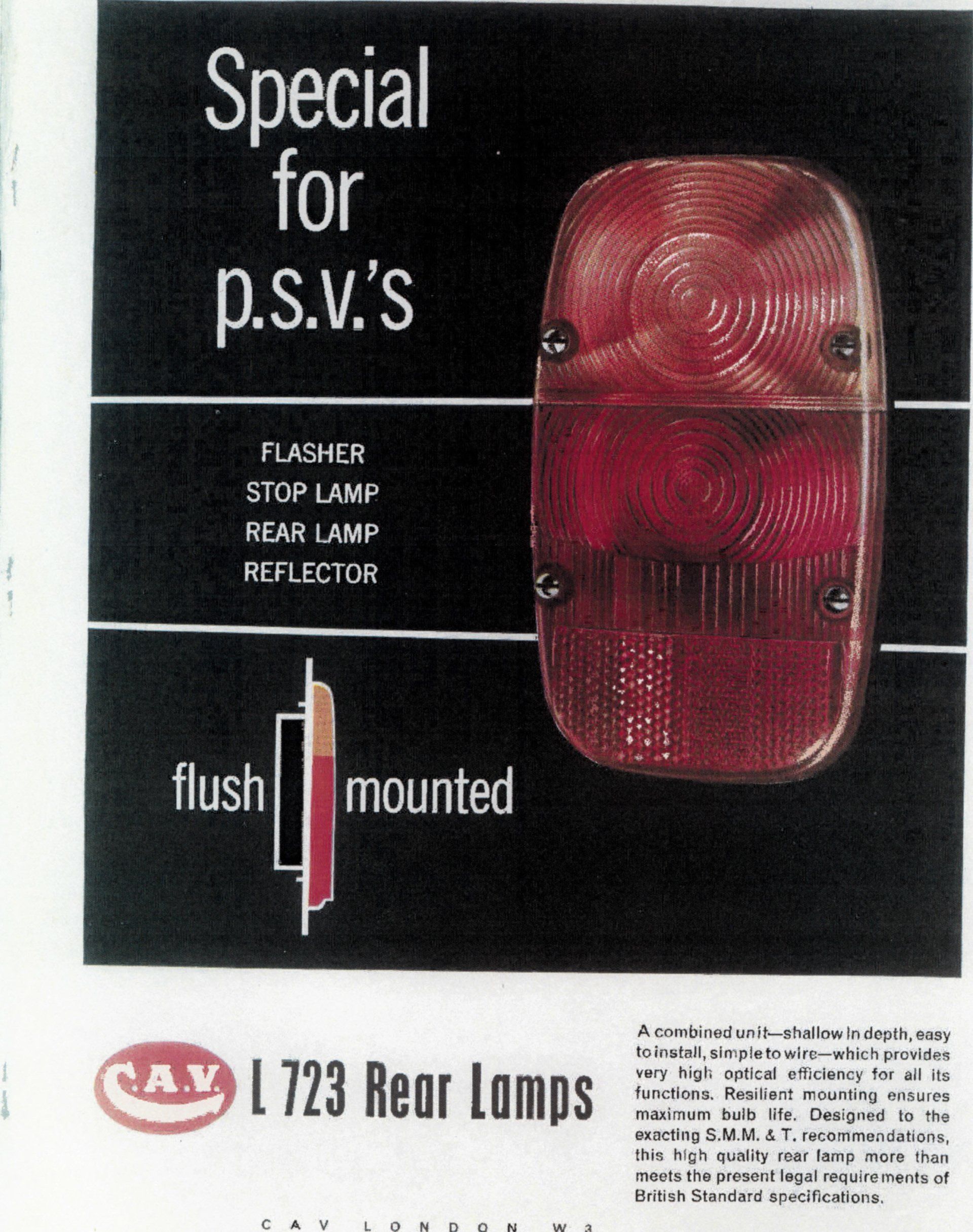

- CAV - electrical control panels; rear light cluster; fog lights; door controls; trafficator dial.

- Chapman - driver's pedestal 'A.D' type seat.

- Clayton Dewandre - floor-mounted saloon fan heaters.

- Frankmann - exterior front traffic indicators.

- Kelbus - destination blind winding equipment.

- Linoleum - luggage locker flooring & interior kick panels.

- Lucas

- exterior headlight units.

- Nesthill - exterior rear-view mirrors.

- Philips - interior fluorescent light units & ballast units.

- Rawlings - 'Vortex' roof-mounted ventilators.

- Simms - electrical control panels & switches.

- Smiths - electrical control panel; overhead air vents.

- Treadmaster - cork-vinyl floor covering.

- Warerite - laminated plastic for window surrounds.

- Weathershields - opening sky-lights.

- Wilmot Breeden

- chrome ash trays; seat back handles; boot & emergency door locking handles.

1960's magazine adverts for suppliers ECW used:

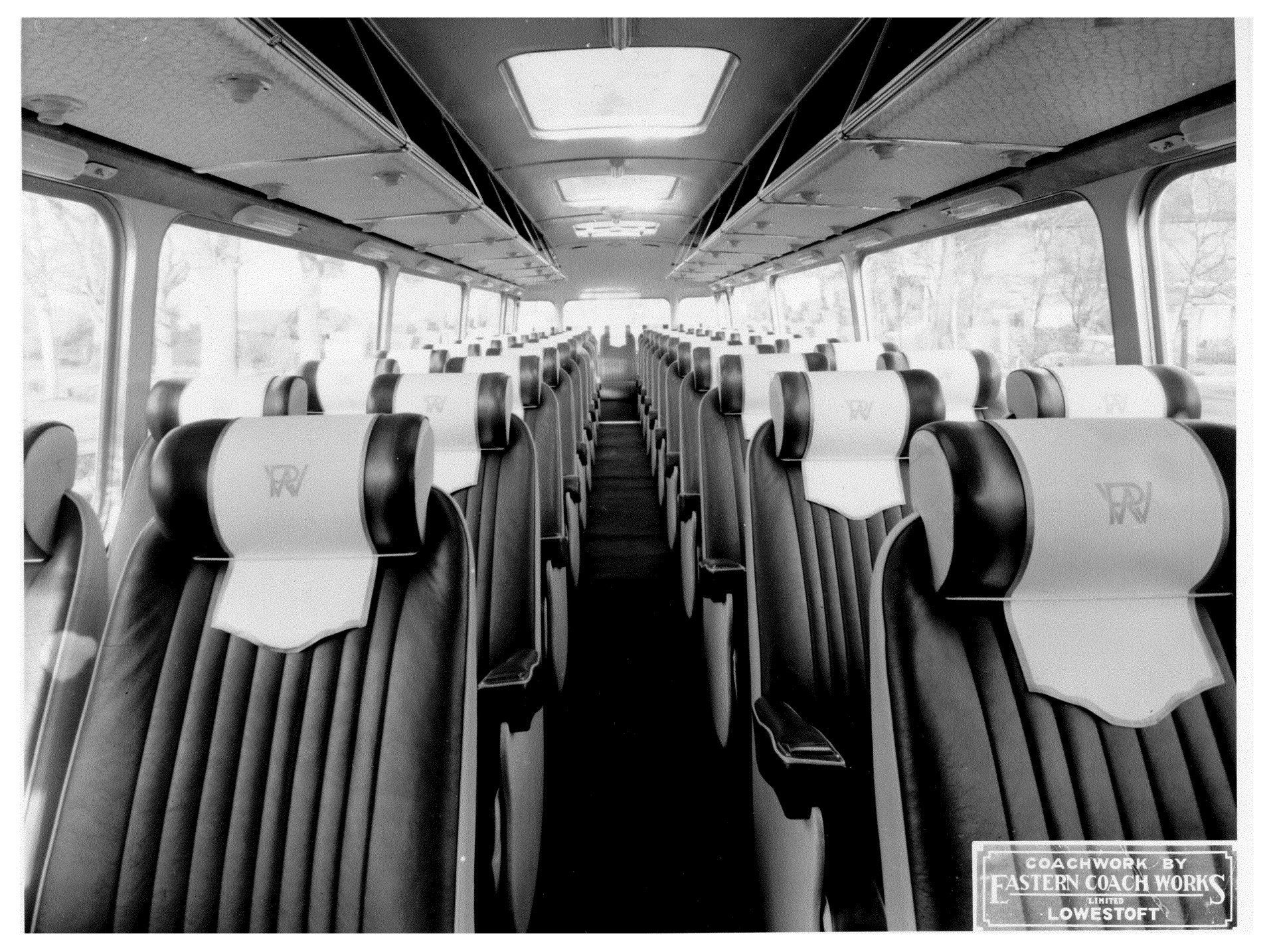

ECW coaches, 1950 to 1963

ECW coaches, 1963 to 1970

View information & photos of our 1968 Eastern Coach Works vehicle.

ECW coaches, 1970 to 1982

ECW ceased building the mk-1 coach body on the Bristol RELH chassis in May 1970. But that was not the end of their coach building activities.

In 1969 AEC designed a rear-engined, 40ft long coach chassis, called 'Sabre'. Only three chassis were built, before Leyland (owners of AEC) cancelled the project.

One 'Sabre' received ECW coachwork, which was an updated version of the bodies they had built on Bristol RELH chassis. It had a higher floor line, deeper side panels, larger windows, plus a new look front & rear (using Plaxton Elite windscreens). New in October 1970 & registered CBU 636J - this unique coach survives & awaits restoration.

Photo credit: Graham Wareham (flickr).

ECW mk-2 coachwork

In spring 1972 ECW started building coach bodies on Bristol RELH chassis again (for the National Bus Company). The design was based on the body-style ECW had created for the AEC 'Sabre' chassis.

Between June 1972 & May 1974 ECW built 85 of these coaches. RED & WHITE had six, new in 1974, registrations: OWO 303M - 308M. None of this batch survive, but 6 of the mk-2 ECW coaches from other fleets do survive.

ECW also built the mk-2 coach body on 22 Leyland Leopard chassis for Greater Manchester PTE between 1972 & 1975.

ECW B51 coachwork

In 1981 ECW updated the front & rear of a 1972 Bristol RELH coach (registration: VHK 177L), so it resembled contemporary Leyland buses of the period. It became the proto-type of new coachwork (which Leyland code numbered B51). 155 were built on Leyland Leopard & Tiger chassis for the National Bus Company in 1981 & 1982.

Unfortunately, many early examples suffered structural problems at the rear. This was because the original body design (of the 1970's) was intended to sit on the Bristol RELH chassis - which extends to the back of the vehicle. Whereas, both Leyland Leopard & Tiger chassis end just after the rear axle. ECW failed to build sufficient additional support into the rear of the body to make-up for the lack of chassis.

The B51 was the last saloon coaches ECW made.

Video about Eastern Coach Works, made by a retired worker.